SUPPORTS & WELDING

The tags can be applied using metal support that can be supplied by a specifically engineered machine, a vibrating stud dispenser, or directly through the head of the robot.

TYPES OF METAL SUPPORT FOR THE TAG

Depending on the type of product to which it will be attached:

- Ring-shaped supports made of a metal wire supplied through the head of the robot for tagging the coils of wire rods.

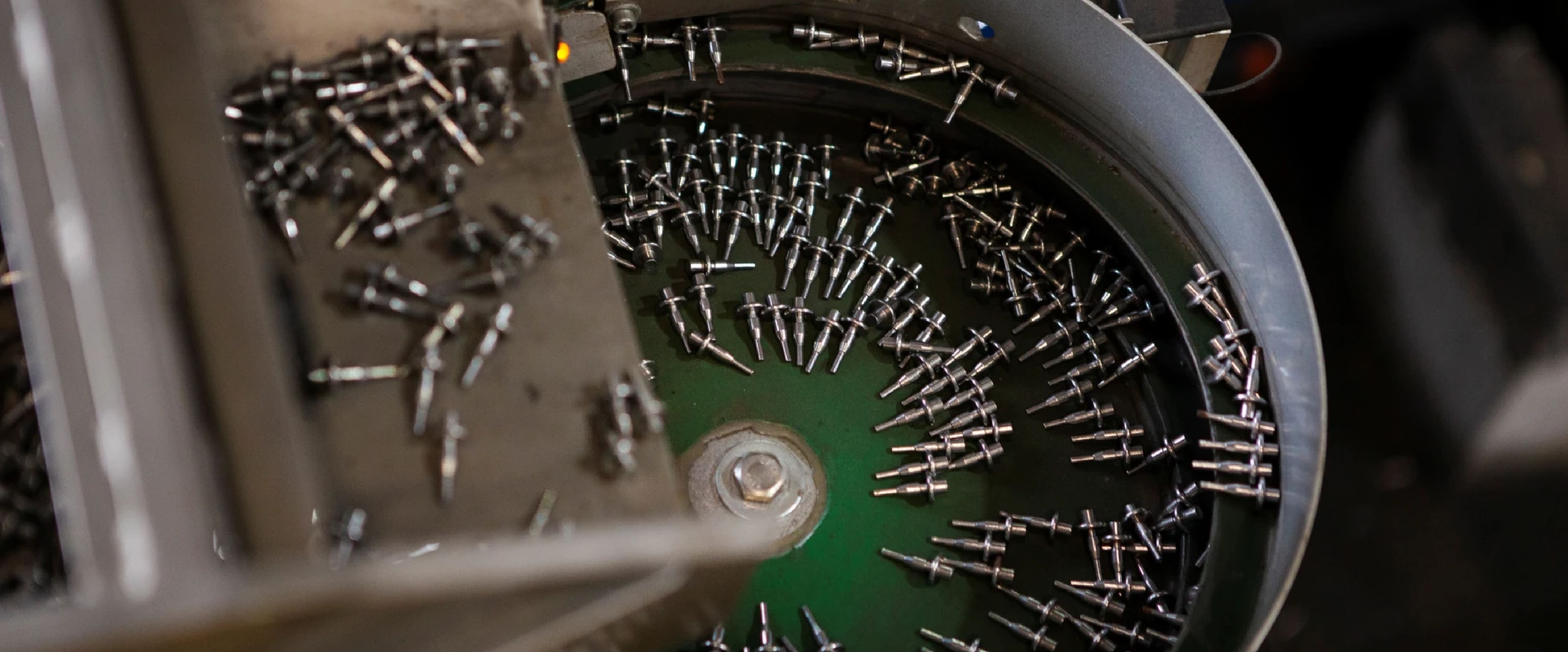

- Studs supplied by the vibrating stud dispenser for tagging bars and bundles.

- Metal supports created by a specially engineered machine for tagging billets, blooms, slabs, etc.

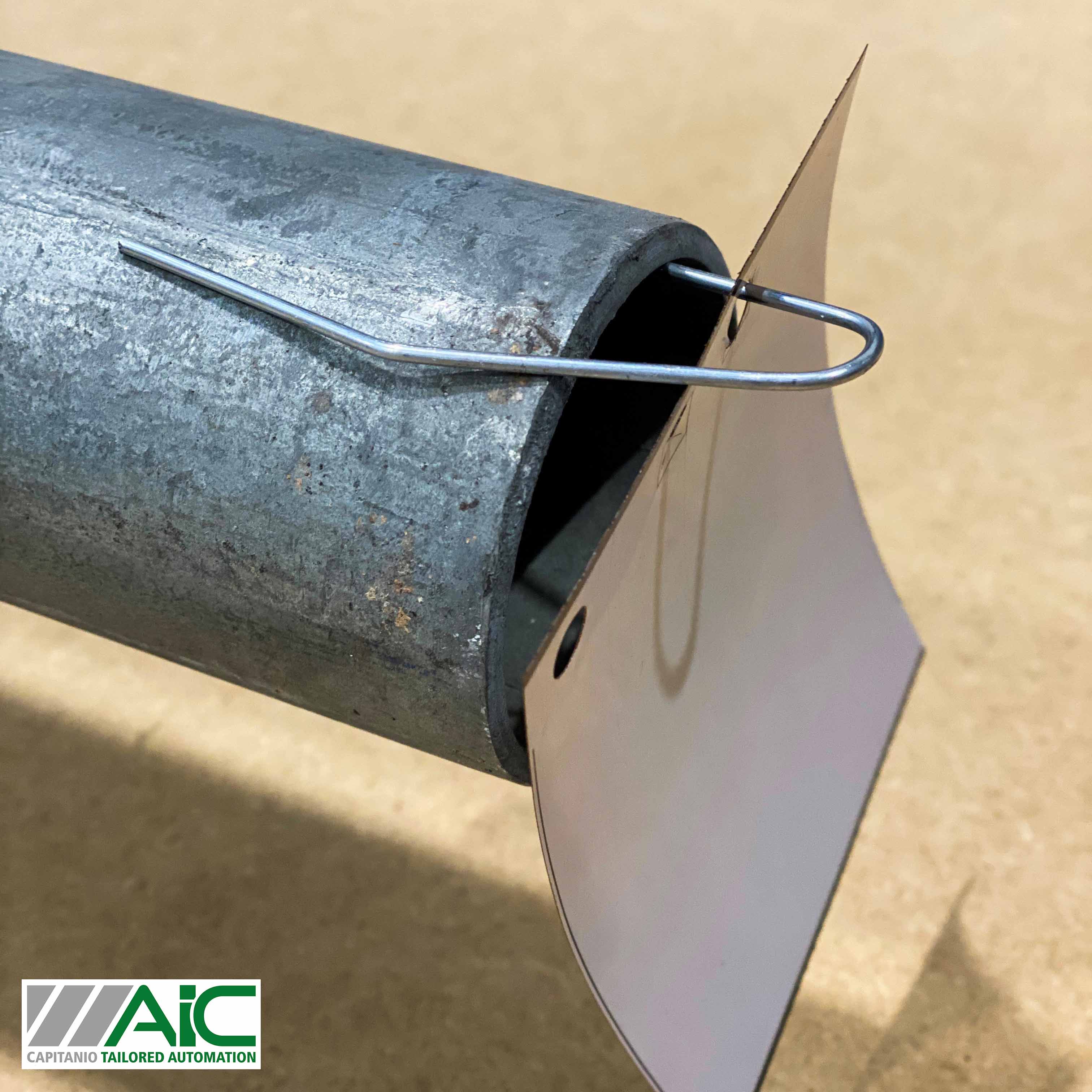

- Clip-shaped metal supports for tagging tubes.

The metal support keeps the printed tag away from the semi-finished or finished products where the material temperature is still high.

For instance, studs are used when the application is done on relatively cold material where it is not a problem to keep the printed tag to a minimum distance between the head of the bundle and the tag itself. For these purposes, a welding machine is installed. There is no need for a welding machine to be used for tagging wire rods, coils and tubes.